QUALITY CONTROL

EQUIPMENT

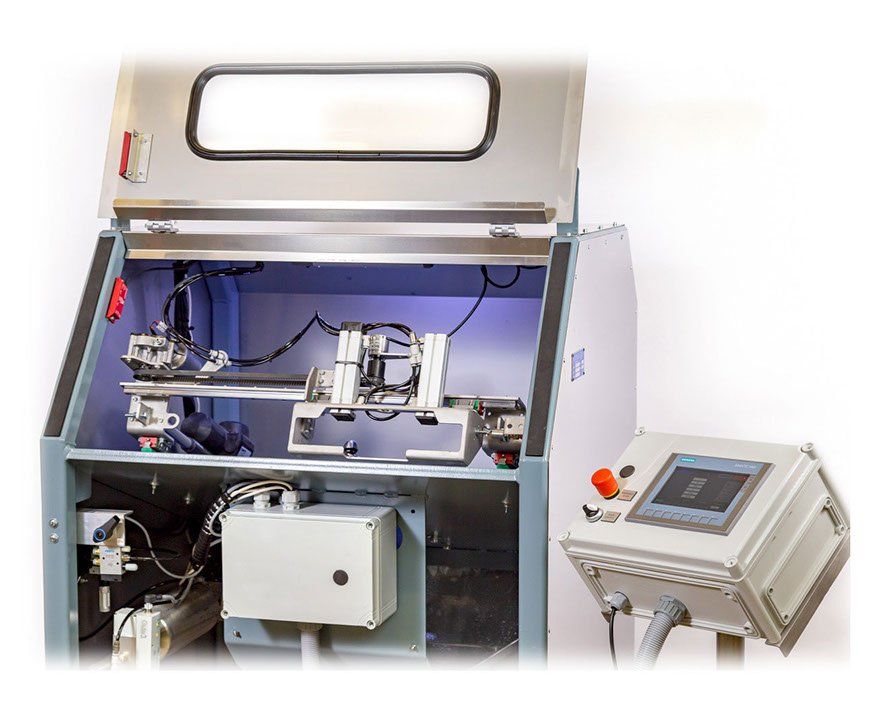

Automatic Pummel Tester

Used for:

Measuring pummel adhesion: the bond strength between the interlayer and the glass. The laminate bond strength must be controlled to avoid problems of de-lamination at low adhesion and impact failure at high adhesion.

The Softeco pummel-testers are made to comply with ASTM C1908-21 Standard Test Method for Pummel Adhesion Testing of Two-ply Laminated Architectural Glass and

EN 14449 – Laminated glass and laminated safety glass - Evaluation of conformity/Product standard. It can also be used for laminated automotive glass.

Conforms to:

EN 14449, ASTM C1908

Features:

The test results are independent of the operator, guaranteeing comparable results.

Principle of operation:

Glass of 300X300mm is attached to the holder with two fixation screws, then press start. The instrument hammers the glass 150mm from the edge, comes back to the starting point and stops.

Technical characteristics:

- Pneumatic hammer, adjustable speed

- Automatic positioning of the laminated glass sample, controlled by PLC

- Safety cover

- Glass sample thickness: up to 24mm

- Glass sample size: 300x300mm

- Angle between glass and support 5°, adjustable with screws depending on laminate thickness

Option:

- Automatic impact pressure control

- Sample size adapter for smaller samples

- Noise control casing (without noise control casing, the noise is between 107 and 77 dBA).