OPTICAL STRESS

MEASUREMENT

EQUIPMENT

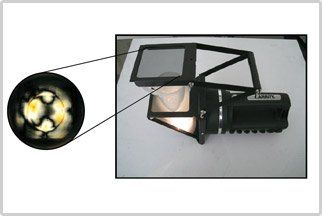

Portable Strain Viewer PSV-100

Used for:

Visual inspection of stresses in glass and plastics

Application:

- Evaluation of temper in glass

- Verification of annealing

- Observation of strains in moulded products

- Detection of weld and flow patterns

- Examination of flow patterns and gate efficiency

- Identification of irregularities due to mould deficiencies or temperature gradients

Residual stress can enhance a product, making it stronger, or contribute to the product’s failure. Surveillance and monitoring of residual stress is an important element of Process and Quality Control in all industries

Principle of operation:

The PSV-100 is a rugged, portable strain viewer for polariscopic examination of transparent or translucent products, revealing strains and stresses due to manufacturing processes.

Features:

The procedure is non-destructive and can be used on flat and curved samples

Technical characteristics:

exists either with linear or circular polarised filters.

battery operated

adjustable working space up to 180 mm

field of view of 75 x 75 mm

Dimensions: 30x9x9cm, light weight 1.4 kg (including batteries)

Options:

PSV-TP: Tint plate, recommended for colour-enhanced pattern observation of annealed parts.