OPTICAL STRESS

MEASUREMENT

EQUIPMENT

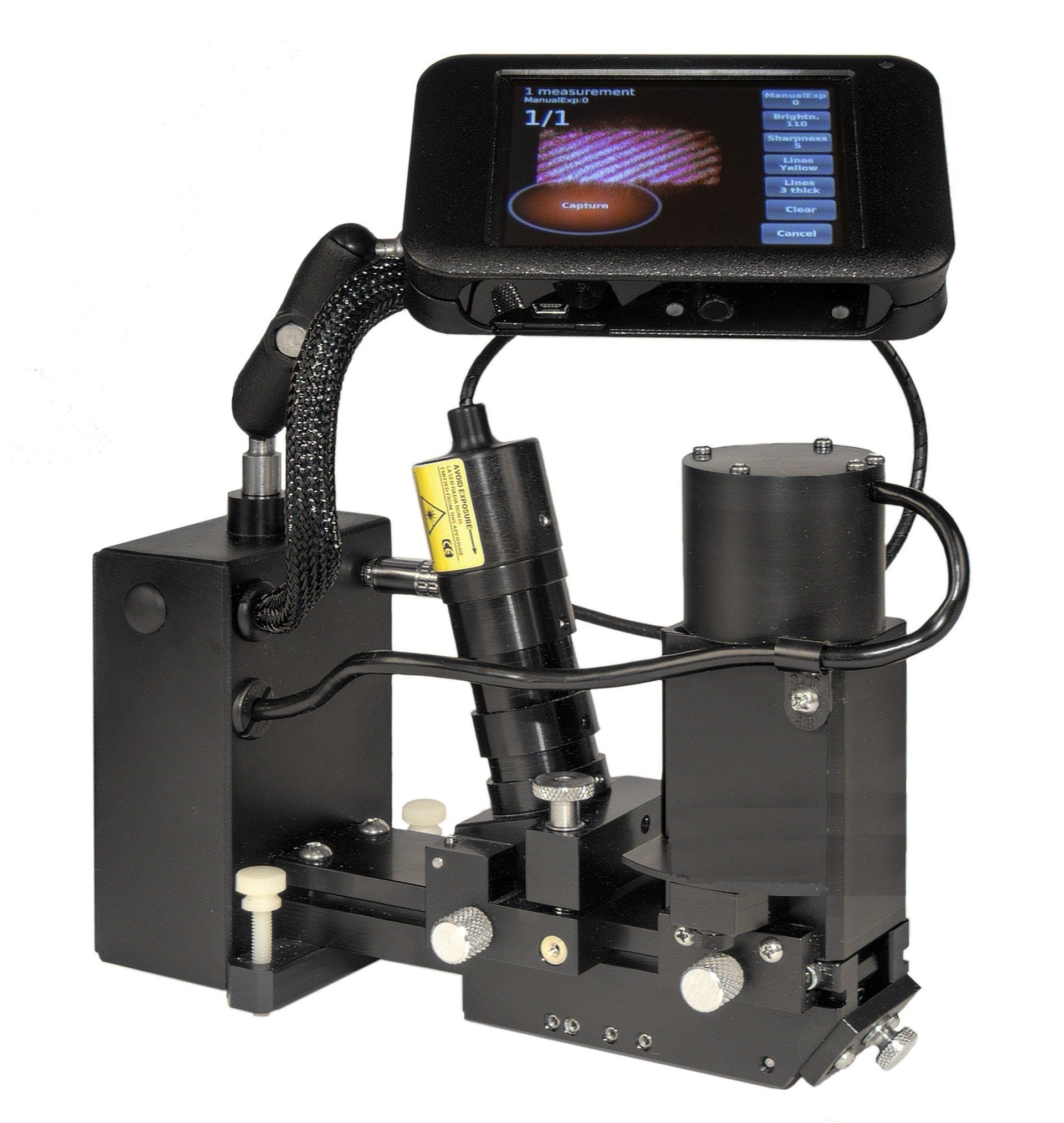

Surface stress meter GASP

Used for:

Surface stress measurement in glass products.

Application:

Tempered Glass and heat strengthened glass:

- to control tempering level and get feedback for tempering furnace adjustment.

- to avoid over-tempering and thus increase capacity and reduce spontaneous breakage risk.

- Factory Production Control according to EN 12150-2 and EN 1863-2, after necessary correlation tables between surface stress and mechanical strength has been established.

- Production Control per ASTM C 1279 in conformance with ASTM C 1048.

Annealed glass, windscreens, TV glass

- to measure residual stress after annealing.

- to control required compressive surface stress on windscreen at areas were average stress is tensile.

Conforms to:

EN-12150, EN-1863, ASTM C1048 and ASTM C1279

Principle of operation:

The GASP polarimeter is used to measure surface stress on the tin side of uncoated thermally treated float glass.Since it measures stress at the surface, the GASP polarimeter performs equally well on laminated or insulated glazing units as long as the tin side to be measured is facing out. It cannot be used to evaluate interior plies or edge stresses.

Features:

The procedure is non-destructive and can be used on flat or curved glass. The measurement can be done in the factory or onsite.

Operator independent measurement, includes a touchscreen, and a SD card to store the measurement information.

Technical characteristics:

- Standard GASP for flat surfaces, or for slightly curved surfaces

- GASP-CS for curved and flat surfaces.

Option:

Available as a standalone Auto-GASP II or as an upgrade kit for owners of standard Laser GASP instruments.

Accessories:

Calplate: Glass reference standard with certified surface stress value. This enables for verifications of the GASP instruments measurement accuracy. In addition it is an ideal tool for operator training.