OPTICAL STRESS

MEASUREMENT

EQUIPMENT

Photoelasticity viewing system

Projected large field polariscope

Used for: identifying the stress patterns on glass and plastic

The photoelasticity test system is a large field polariscope used to visualize and measure stress in virtually any size of glass or plastic product.

Consists of:

reflecting screen, projector, analyser and polarizing slide.

Principle of operation:

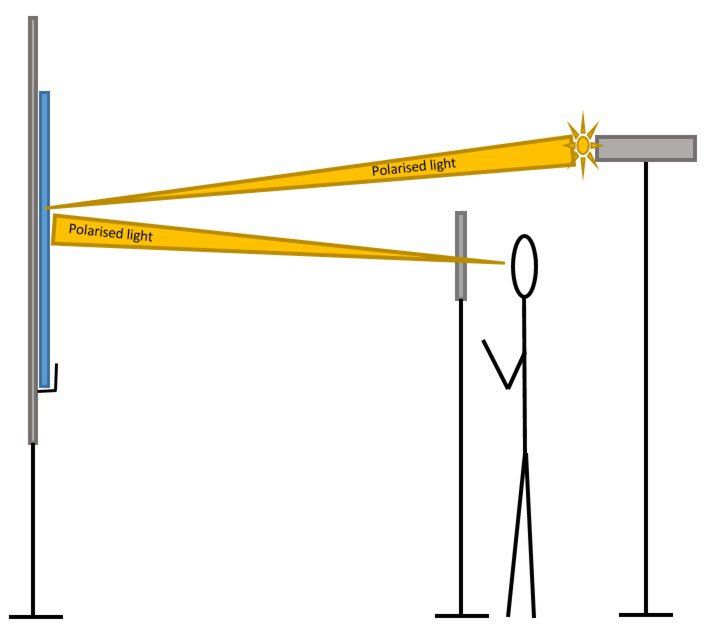

The polarizing slide is placed in the diascope (the polarizing direction has to be oriented at 45° vs. horizontal). The analyser is composed of another linear filter placed at 90°from the first. The analyser and diaprojector shoud be side by side and at a distance of 4 m of the reflective screen.

The glass sample is placed between the diaprojector and the reflective screen. The light will pass through the sample and is reflected back to the analyser. This allows the visualisation of the stress pattern.

Technical characteristics:

Reflecting screen

Plastic screen with specific metallic silver painting, designed to avoid depolarized reflection and keep the polarising axes intact. Equipped with 2 pairs of supporting fingers located at 1,15m from the ground on which the glasses (sample to evaluate and reference sample) will be placed parallel to the screen.

Polarising slide

Slide with linear or circular polarizing filter

Analyser

For stress pattern visualisation only: circular or linear polarising filter. Analyzer dimension: 100mm x 100 mm.

Optionally SA-100 for stress measurement.