OPTICAL STRESS

MEASUREMENT

EQUIPMENT

Softeco Polariscope

Used for:

- visual inspection of stresses in glass

- Verification of stress pattern of glass

- Detection of irregularities caused by molds

- Detection of faults caused by temperature gradients

- Detection of faults due to quenching irregularities

Tempered glass products should be controlled as to stresses to ensure their conformity to standards. A strain viewer is a practical, non-destructive apparatus to control products as well as production conditions.

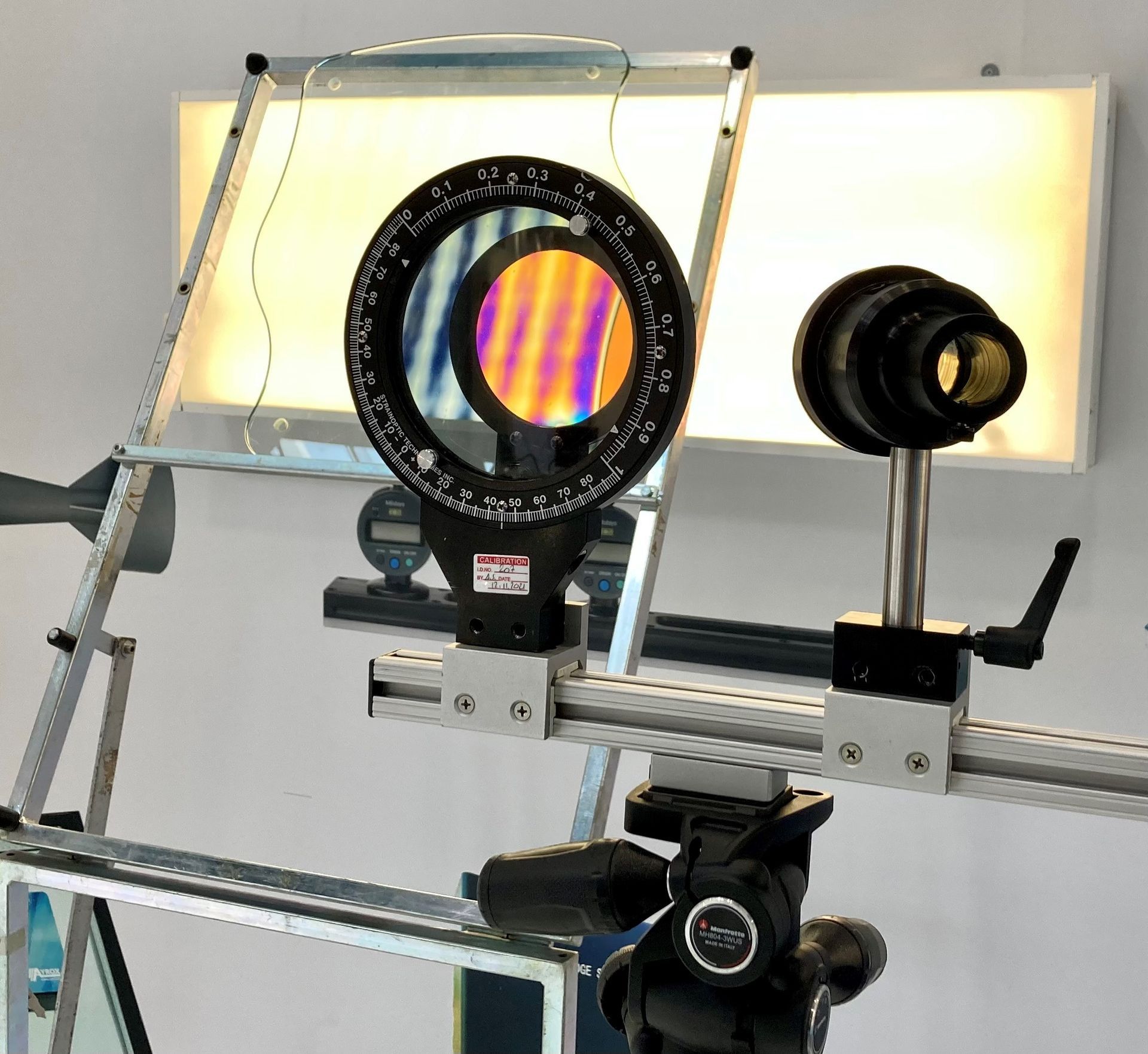

Principle of operation:

With the apparatus a stress pattern can be seen and stress- defects detected in colour. Faults or changes in production can be followed by comparing the stress pattern of a test- piece with a sample previously tested and known as a good one.

Features:

The procedure is non-destructive and can be used on flat or curved glass or plastic

Technical characteristics:

SOFTECO strain viewer consists of a light source with polarizing filter (polarizer), and another polarizing filter (analyzer) with a wave retarder.

No glass size limitation

Movable construction

Custom sizes from 10x10cm to 200x150cm