PVB

SHAPING AND CUTTING

PVB shaping or stretching

for windscreen production

Used for:

PVB Shaping or stretching prepares PVB interlayer sheets for the production of windscreens.

It gives both commercial and economic benefits to the windscreen producer:

- increases the aesthetic and comfort values of top-shaded windscreens.

- gives savings of 15-25 % with top-shaded PVB and 10 % with uniformly coloured PVB and wedge PVB.

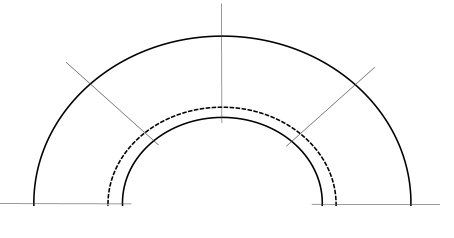

Principe of operation:

The procedure uses PVB’s natural behavior from temperature differences. The machinery can be used for:

- shaping top-shaded or uniformly coloured PVB with the minimum radius of 2100 mm

- stretching PVB to optimal thickness within quality requirements

- cutting clear and tinted interlayer at any desired angle between 0-25°

- shaping, stretching and cutting machines can also be operated individually.

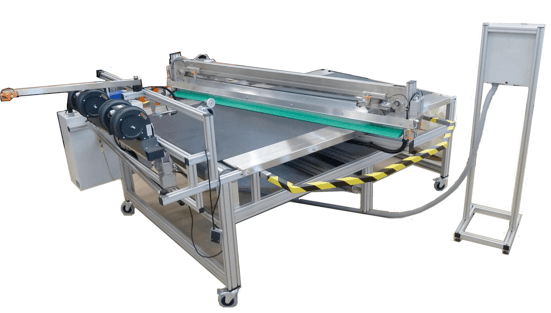

Features:

According to the user’s needs :

- separate cutting with drive, operation width 1250 – 1700 mm

- antistatic treatment of PVB

- manual stackers

- humidity measurement

Technical characteristics:

- Standard speed: 3m/min or 6m/min

- standard widths 1250 and 1500mm, other widths possible