PVB

TREATMENT

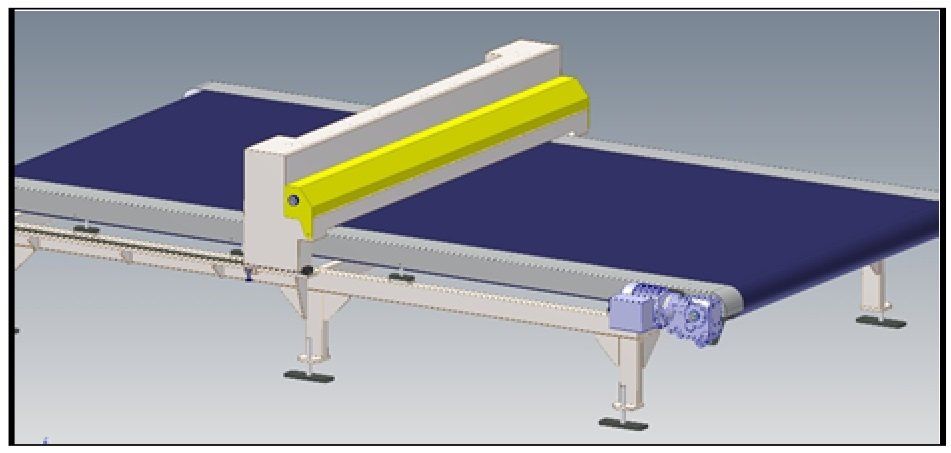

SMF Shaping Machine

for PVB interlayer

Used for:

The SMF machine shapes the PVB interlayer to the desired curvature or stretches it to optimal thickness within the quality requirements of the windscreen.

It is adapted for shaping:

- clear, tinted and top-shaded interlayer

- refrigerated and interleaved PVB

- PVB up to 1200 mm wide

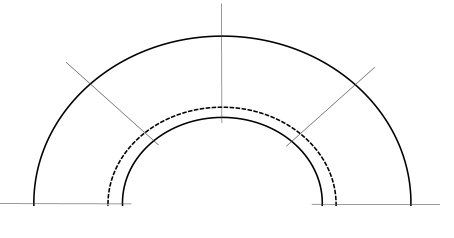

- to the curvature of a minimum radius of 2100 mm

- with the speed of 3 m/min (SMF 3) or 6m/min (SMF 6)

The flexible operation and adjustment of the machine permits shaping for short production series.

Principle of operation:

The shaping process takes advantage of the thermoplastic properties of PVB.

The interlayer is drawn from the roll through the heating, stretching, and pre-cooling zones of the machine. The process is PLC controlled. The settings for production parameters, e.g. curvature angle or production speed can easily be adjusted or changed without interruption of the process.

Features:

- antistatic treatment of PVB

- controllable cooling system for installation in high ambient temperature

- working widths of 1250 and 1500 mm

Technical characteristics:

Standard working widths: 1250 and 1500mm, other widths possible.

Operating speed: 3m/min and 6m/min

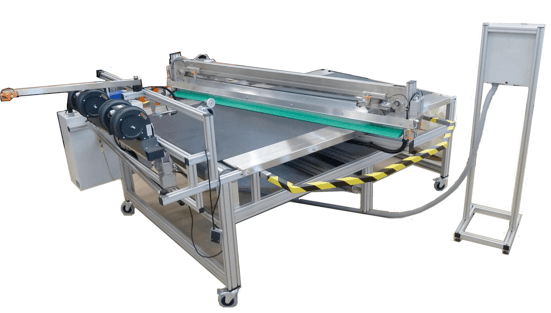

FCM Cutting Machine

for PVB interlayer

The FCM machine cuts automatically the PVB interlayer to the desired angle and length for windscreen production. Cutting can be performed l l l, / / / or / \ / \ .

The machine is adaptable for cutting

- clear, tinted and top-shaded PVB

- shaped and unshaped interlayer

- refrigerated and interleaved PVB

The FCM is the cutting unit of the PVB SHAPING LINE, but is well adapted for independent use. The working width of the FCM is 1250 mm. Different widths are available.

OPERATION

PLC controlled cutting is performed automatically by a horizontally moving wheel. All process parameters can be adjusted during production run without the need to stop the production.

The machine can also be operated manually.

The operation speed is synchronized with the speed of the shaper SMF or the relaxation unit REL. For unshaped, stretched or unstretched PVB the cutting speed can be adjusted according to necessity up to 6 m/min

CONSTRUCTION

MAIN CHARACTERISTICS

- aluminium profile frame

- full size conveyor belt for feeding and unloading

- pneumatic wheel movement

- cutting performed under safety covers

ACCESSORIES

- PVB roll support

- interleaf rolling-out system for interleaved PVB, if used individually without the machines SMF and REL

- trays for cut blanks and trolley for trays

| SPECIFICATIONS | FCM-1250 |

|---|---|

| Cutting angle | 0 - 25 º |

| Maximum working width | 1250 mm (50 inch) |

| Production capacity | 1 - 5 pcs/min |

| car windscreen sheets | |

| Width | 2200mm |

| Height | 1500mm |

| Lenght | 3000mm |

| Installed power | 1kW |

| Compressed air | 6 bar |

| Voltage | 230/400V, 50Hz, 5 wire system |

| (other voltages on request) |