QUALITY CONTROL

SERVICES

GENEVA AGREEMENT 1958

For safety reasons the EU countries and some 15 European countries have agreed about approvals for motor vehicle equipment and parts. All automotive components shall meet given requirements and shall be approved according to about 113 different ECE R rules.

Automotive glazings are covered by the ECE R-43 rule.

MARKING

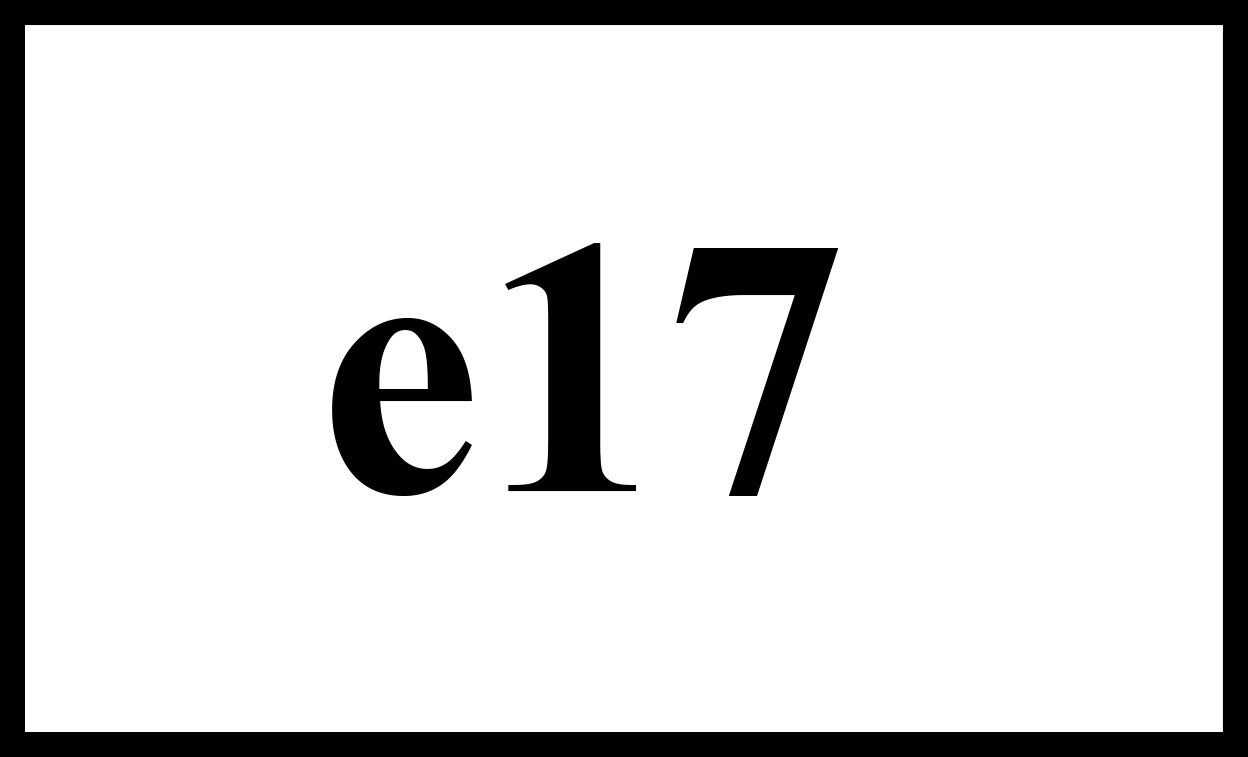

The products approved according to ECE R-43 rule are marked (E) and the products approved according to EU-directives are marked [e].

ECE R-approvals are accepted as equals to approvals according to directives. The number in the marking indicates the country having granted the approval.

E. g. (E 17) has been granted by Finnish authorities, and is valid in all countries recognizing the E approval.

APPLICATION FOR APPROVAL

Producers in a country which has signed and ratified the Geneva 1958 agreement can get the approvals from their own government if the country has accredited testing laboratories.

Producers of a non-signatory country shall nominate a representative in a signatory country for approval purposes. This company will be responsible for the approvals and for the producer’s quality. The representative will arrange the testing and apply for the approvals from his local transport ministry.

The approvals thus obtained will be valid in all signatory countries and in other countries recognizing the approvals.

APPROVAL PROCEDURE

LAMINATED AND TEMPERED AUTOGLASS

The products are tested first and the factory’s quality plan has to be approved and the factory audited. Most tests will be made at the factory, others in the accredited laboratory of the signatory country. After obtaining successful test results the approvals will be granted.

Annual audits

Every 6-12 months the factory will be audited, the quality control system and documentation are inspected to ensure that the production fulfils the requirements.

After each audit a certificate is issued by the testing authority.

All test results and inspection reports are permanently registered by the ECE secretariat in Paris.

For windscreens each model has to be approved separately. Sidelites and backlites have group approvals by thickness. No testing of installed glass is required.

For automotive glasses the factory must have testing facilities with strictly defined minimum equipment.

MIRRORS

The requirements of rear view mirrors are totally different from those for automotive glasses. Each mirror model shall be tested for the qualities of mirror-glass, frame and fixation to the vehicle.

If these tests are successful no further testing is required. No factory audits nor quality system inspection are done.

For mirrors the rules do not require any testing laboratory in the factory, but of course customers demand constant high quality, and some testing should be done for commercial reasons.

Although there are no specific requirements for QC in the mirror rule, the general principles of ECE R do govern also mirror manufacturing :

- 2.3 The holder of the approval must in particular

- 2.3.1. Ensure the existence of procedures for effective control of the conformity of products ( vehicles, equipment or parts ) to the type approval.

- 2.3.2. Have access to the testing equipment necessary for checking the conformity to each approval type.